begins in the fields of durum wheat

the secret of excellence is in the grain

water and semolina silent sculptors of the ideal dough

The art of pasta making begins in the durum wheat fields. In fact, the secret of excellence is enclosed in the grain of this cereal: it contains the flavour and all the nutritional elements that make pasta delicious for your palate and healthy for your body. The proteins give the pasta texture so that it will not be overcooked and heavy to digest. The water must also have special properties, such as maximum purity, so as to obtain a genuine dough.

A century of milling history has taught us to choose the best ingredients for an exclusive pasta.

The selection process begins in the fields, where the durum wheat is cultivated with special care. Here is a more detailed description:

Cultivation: our journey begins in the fields, carefully chosen for their properties. Indeed, the combination of climatic and morphological conditions in the area of origin has a profound effect on the taste and quality of the wheat. It is like a fingerprint, which makes each production unique and unmistakable.

Harvesting: when the ears reach perfect ripeness, the harvest begins. A crucial moment, where any unforeseen event can compromise the quality of the harvest. The threshing machines separate the grain from the ear with particular precision.

Selection: the grain deliveries are subjected to careful product and organoleptic analysis. Only those consignments that meet our strict standards are admitted to the subsequent processing stages.

Cleaning and storage: the selected wheat is thoroughly cleaned to remove all traces of impurities. Finally, they are stored under controlled conditions of temperature and humidity to preserve their properties for milling.

The selection of durum wheat is a meticulous process that requires a profound knowledge of the grain and its characteristics, but at the same time indispensable for producing high quality pasta.

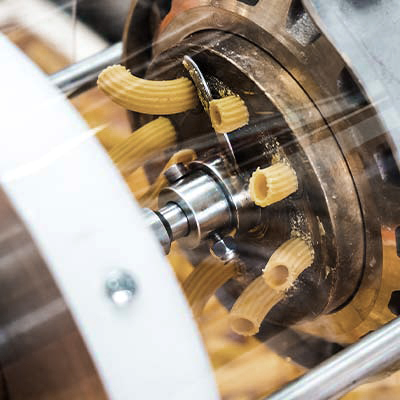

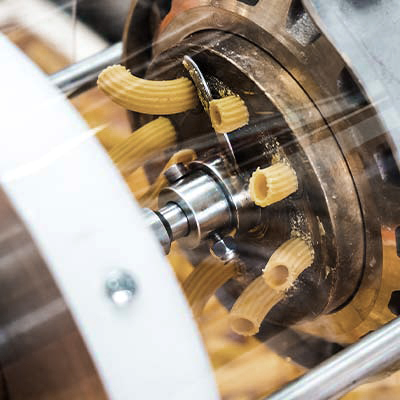

Made from durum wheat semolina and water, bronze-drawn pasta undergoes a production process that includes bronze drawing and very slow drying, giving it an unparalleled quality.

One of the most crucial steps is selection, a process that requires a perfect combination of technology and human sensitivity. Indeed, this selection is not limited to the outward appearance of durum wheat, but also to laboratory parameters such as specific weight, moisture and protein content.

Through milling, durum wheat is crushed so as to separate the semolina from the less noble external parts of the grain. The quality of the semolina obtained, in terms of grain size and protein content, has a direct influence on the characteristics of the final pasta, such as its hold during cooking, roughness and flavour.

The kneading process is fundamental for the development of the gluten mesh, a three-dimensional protein structure that imprisons the starch granules and gives the dough elasticity and toughness, allowing it to keep its shape after cooking.

Drawing, an extrusion process, allows the dough to be given its desired shape through the use of bronze inserts that give porosity and roughness to the surface of the dough.

Drying, which is essential for the quality and shelf life of the pasta, gradually removes the water from the dough. A slow process at low temperatures preserves nutrients, improves cooking and intensifies the flavour of the grain.

Once the production cycle has been completed, the pasta batches are subjected to a series of rigorous checks to verify their compliance with reference quality standards. This activity is essential to ensure food safety and meet consumer expectations.

Made from durum wheat semolina and water, bronze-drawn pasta undergoes a production process that includes bronze drawing and very slow drying, giving it an unparalleled quality.

One of the most crucial steps is selection, a process that requires a perfect combination of technology and human sensitivity. Indeed, this selection is not limited to the outward appearance of durum wheat, but also to laboratory parameters such as specific weight, moisture and protein content.

Through milling, durum wheat is crushed so as to separate the semolina from the less noble external parts of the grain. The quality of the semolina obtained, in terms of grain size and protein content, has a direct influence on the characteristics of the final pasta, such as its hold during cooking, roughness and flavour.

The kneading process is fundamental for the development of the gluten mesh, a three-dimensional protein structure that imprisons the starch granules and gives the dough elasticity and toughness, allowing it to keep its shape after cooking.

Drawing, an extrusion process, allows the dough to be given its desired shape through the use of bronze inserts that give porosity and roughness to the surface of the dough.

Drying, which is essential for the quality and shelf life of the pasta, gradually removes the water from the dough. A slow process at low temperatures preserves nutrients, improves cooking and intensifies the flavour of the grain.

Once the production cycle has been completed, the pasta batches are subjected to a series of rigorous checks to verify their compliance with reference quality standards. This activity is essential to ensure food safety and meet consumer expectations.

Semolina production begins with the selection of the best varieties of durum wheat to be milled into semolina. This process must be carried out with extreme care so as to preserve the nutritional properties of the valuable raw material. Indeed, each grain contains a multitude of nutrients, which must be overheated as little as possible to remain intact. For these reasons, high-quality semolina gives pasta its distinctive flavour and unique texture. It is the result of meticulous work where every detail is carefully observed.

When you taste pasta made from top quality semolina, you are appreciating the outcome of a production process that has brought out the best in durum wheat. This is why we devote our utmost attention to semolina.

There is one element that plays a key role in the preparation of the dough: water. Let’s see why during the different stages:

Kneading: The durum wheat semolina is mixed with pure water in special kneading machines.

Gluten formation: During kneading, the starch and proteins in the semolina bind with the water to form gluten. Gluten is a protein network that binds hydrated starch granules. This protein network gives the dough an elastic and resistant consistency, which allows the dough to maintain its structure during cooking.

Grain size: the grain size, i.e. the diameter of the particles that make up the semolina itself, influences the final texture of the dough. A ‘coarser’ semolina better enhances the properties of the grain.

Drawing: In the drawing phase, the dough obtained is then shaped by the dies, which determine its shape. The water used in the dough helps to shape the dough during this phase.

Slow drying: Drying represents the most delicate moment of the entire production cycle. During this phase, the water is slowly removed from the dough, allowing the dough to assume its final shape.

In conclusion, water is essential for the preparation of pasta and must fulfil particular characteristics to perform its activities in the production cycle.